Cost out – Implementing Lean Value Streams

Company:

Miba Friction Division

Laakirchen, Austria

Information:

1B € manufacturer of high-tech composite-components for clutches and brakes in automotive and off-road applications

Period:

February 2018 – January 2021

Role:

- Managing Director Operations

- COO Friction Division

- Interim Assignment

Responsibility:

- 200 Mio € business, accountable for six global sites, 1300-employees

- In particular: the plant was the Slovak plant, about 650 employees, 65mio Eurosales

Situation:

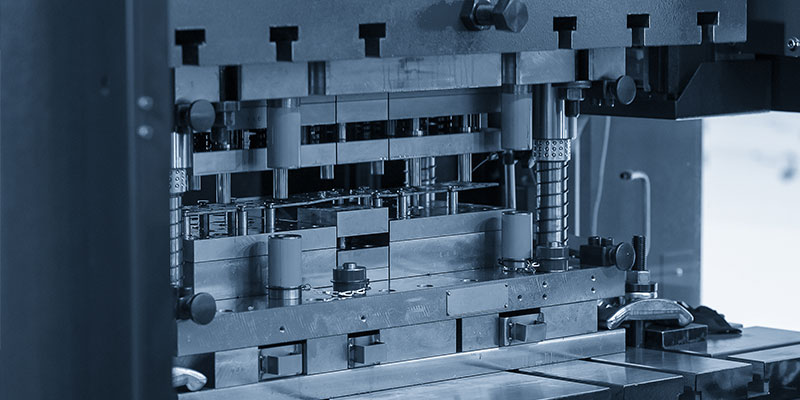

- The plant was a metals fab shop – stamping with subsequent operations.

- EBIT and ROCE dropped below benchmarks as the plant managed a 35% upturn in volume.

- Lead times were too long, information on orders was unreliable, costs and inventories were too high. Customer relationships were stressed.

- The task was to transform the plant to a higher volume, reduce throughput times and bring transparency to the processes.

- The aim was to bring EBIT and ROCE – at higher volumes – above the benchmarks.

Challenge:

- The operations were set-up in work centers – creating waste in movement and wait times.

- SAP and scheduling software were only partially implemented with work arounds.

- The product portfolio was wide, and references had complex up to 14 routings steps.

- Delivery reliability was in the eighties versus a customer commitment of ninety eight %.

- The plant and the team were operating in ways established ten years ago.

Execution:

- While the overall operation may have been overwhelming, I recognized that there were opportunities to segmentize the product portfolio. Based on the segmentation work centers could be reconfigured into value streams to drastically reduce lead times, inventories, and costs.

- I strengthened the leadership and trained the plant team on lean manufacturing with value streams to get buy-in and excitement.

- I aligned the plant team with corporate and external resources and together we took a deep dive into analyzing the current state and based on it developed the future state.

- I tackled the most difficult part early on: realigning the organizational and reporting structures and convincing key players of the need to change.

- I attended work meetings to encourage, give tips, and expel when necessary. There were regular reviews to move the project forward, eliminate obstacles to field support, and adjust.

- Initially we wanted to separate out one value stream. Once the team realized the positive effects, they, with some encouraging and challenging, came up with another four value streams.

- Presenting the future state with EBIT and ROCE commitments to Corporate Management lead to approvals for investments.

Result:

- A proud, engaged team that finished the project within 24 months.

- Over 16 mio Euro invest with a payback of less than 2.5 years.

- Reduction of lead times by up to 95%, from 10 days to a few hours.

- Reduction in direct labor. Reduction in WIP and overall inventory by 30%

- EBIT and ROCE improvements will be evaluated after Corona distortions.